Changing the uphall on a DY centre plate from wire to webbing

CHANGING THE UPHAUL ON THE CENTRE PLATE FROM WIRE TO WEBBING by Andrew Matthews

Moving from wire to webbing is a better solution, particularly in terms of safety for your crew.

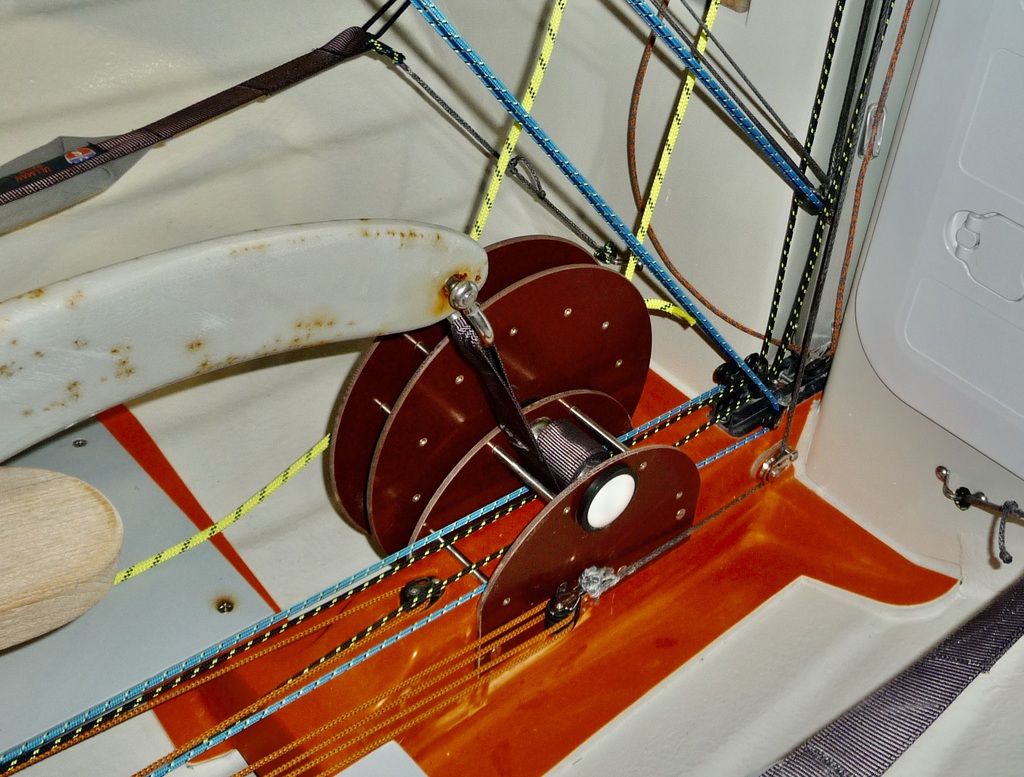

It is pretty straightforward. First, find out how your wire is held into the small drum around which it winds. If you remove the black endcap on that drum (usually held in by a corroded and now unthreaded screw!) and take the tension off the wire, you should be able to fish the end of the wire out of the drum with long nosed pliers. The end of the wire is usually knotted off to prevent it going back through the drum. If you are not going to use the wire again, cut the knot off, if you cannot get the knot out. Replace the end cap (with a drop of Loctite or superglue on the screw if it is very loose.

You need enough webbing (the same stuff as you use for foot straps) to ensure that, with the plate right down, there are still three or four turns on the little drum plus a little to spare for an eye (see below). The turns take the weight of the plate, rather than the rather inadequate fastenings you will make. If your wire has a few turns left on the drum when the plate is fully down (as it should), it will be a good guide to the length of webbing required.

Choose two small flat headed machine screws and tap two holes in the little drum horizontally to each other to receive them. If you don’t have any taps, just drill slightly undersized, drop some oil onto the machine screws and tap them in by force. Withdraw the screws. Fasten one end of the webbing onto the drum using the machine screws. This will not be a load bearing joint (the turns will take the load) – it is just a holding job.

On the plate end of the webbing make an eye big enough for you to pass through whatever shackle you use to attach the webbing to the plate with. This is easily done using one of the proprietary clamp fittings you can buy from chandlers. Basically, you double the webbing back on itself to form a loop and fasten the double backed part onto the standing part. I finish off with some stitching using sailmaker’s twine to ensure there is no loose end to snag on anything. When the eye is made you can double the outer edges back in to make the eye smaller and stronger.